- Photocatalytic deodorization process system / UV light touch equipment

- Low temperature plasma deodorization system / Electrostatic treatment equipment

- Low temperature plasma + UV photodecomposition all-in-one purification machine

- High energy ion deodorization system / Equipment

- Activated carbon adsorption deodorization process system / Activated carbon absorption tower

- Activated carbon adsorption / desorption + catalytic combustion equipment

- Exhaust gas scrubbing absorption tower / Packing spray absorption tower

- River Basin Ecological Comprehensive Treatment Project

- Integrated sanitary sewage treatment equipment

- Reclaimed water reusing equipment

- Spray deodorization system of plant liquid

Lucheng Environmental Protection Technology

Add: Yanshan Village, Chongxian Town,

Yuhang District, Hangzhou, China

(Longdong station of bus 338)

P.C.: 311106

Tel: +86-571-89180368, +86-13805776025

Fax: +86-571-89180370

Email: 523884910@qq.com

URL: www.luchenghb.com

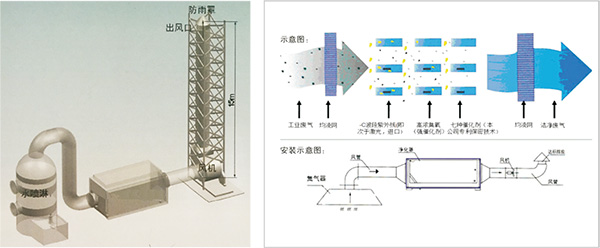

Photocatalytic deodorization process system / UV light touch equipment

The company's UV light deodorization process system mainly uses the ultraviolet beam to decompose the oxygen molecules in the air, produce free oxygen, because the free oxygen carrying positive and negative electron imbalance, so with the oxygen molecules, and then produce ozone, the use of ozone strong The oxidation of the organic matter in the smell of organic matter such as benzene, toluene, xylene, hydrogen sulfide into the photo-oxygen catalytic purification, in the ultraviolet radiation with ozone oxidation reaction, the final decomposition of harmless inorganic, such as water, carbon dioxide The

Technical features:

Without any side effects. Completely beyond the traditional processing device, in the presence of people in the environment continued sterilization, dust, no toxic side effects on the human body. Can be widely intercepted to kill all kinds of bacteria in the air, the test proved that the Staphylococcus aureus, Bacillus subtilis, black variant spores and natural bacteria kill rate of 99.9% or more, the effective removal of respirable particles, reaching 1-10 million Grade cleanliness.

Clear the smell of harmful gases, the primary electrons in the electric field to get accelerated, the impact of oxygen in the air. When the energy exceeds the ionization potential of the oxygen molecule, the oxygen molecules are rapidly ionized. Loses electrons becomes a positive polarity oxygen molecules of oxygen ions (O2+), releasing electrons to neutral with another molecule of oxygen into negative oxygen ions (O2-), oxygen ions are the result of the polarization and neutral oxygen molecules adsorbed open into O2+, O2-, O2-, O2 and other oxygen ion group gathered, has strong oxidation, can in a very short period of time will pollute the air oxidation of harmful components broken down into harmless products and water; O2+e(3.6eV)→·O+OH2O+e(5.09eV)→·OH+HO+·OH→·OH2.

Studies have shown that the oxidation potential (2.8 eV) of the active radical OH is 35% higher than the oxidative potential (2.07 eV) of the highly oxidizing ozone. · OH radicals react with organic matter several times in magnitude.Moreover, the reaction of OH radicals to oxidative contaminants is optional and can lead to chain reactions that directly oxidize most of the harmful substances in the air to carbon dioxide and water or minerals.

Performance advantages:

In addition to odor: can effectively remove volatile organic compounds (VOC), inorganic, hydrogen sulfide, ammonia, thiols and other major pollutants, as well as a variety of malodorous gases, deodorization efficiency of up to 99% or more, deodorizing effect greatly exceeded (GB14554-93) promulgated by the State in 1993 and the "Integrated Emission Standard for Air Pollutants" (GB16297-1996) promulgated in 1996.

No need to add any material: only need to set the appropriate exhaust pipe and exhaust power, so that odor / industrial waste through the device deodorization decomposition purification, without adding any substances involved in chemical reactions.

Adaptability: light oxygen catalytic exhaust gas treatment equipment can be adapted to high concentrations, atmospheric, different industrial waste gas deodorization, purification treatment. 24 hours a day can work continuously, stable and reliable operation.

Low operating costs: light oxygen catalytic exhaust gas treatment equipment without any mechanical action, no impatient tone, no need to manage and routine maintenance, only for regular inspection, the equipment low energy consumption, equipment, low wind resistance ≤400pa, can save a lot of exhaust Power consumption equipment.

Equipment covers an area of ??small, light weight, suitable for compact layout, the venue of the special conditions.

High-quality imported materials manufacturing: fire, anti-corrosion performance, equipment, safe and stable performance, the use of stainless steel, equipment life in more than fifteen years.

Using the most advanced international technology concept, can be completely decomposed toxic and hazardous substances in industrial waste gas, and can achieve the perfect deodorization, purification effect, the decomposition of industrial waste gas can be achieved to achieve harmless emissions, no secondary pollution, To achieve the role of efficient sterilization.

Equipment has a safe, explosion-proof features, has been through the national explosion-proof electrical product quality supervision and inspection center of the explosion-proof certification, can be widely used in oil (gas) field, petrochemical, pharmaceutical and other high demand for explosion-proof industry.

Technology Scope:

It is mainly used in chemical industry, paper industry, pharmaceutical industry, food industry, tire and rubber production plant, automobile production plant, paint spraying plant, sewage treatment plant, sludge treatment plant, waste disposal plant, tanneries, Production, beverages and farms, pesticide production and tobacco industry, and many other areas of odor and odor treatment.

Technical Data Sheet:

| model | Air volume m3/h | Power KW | Dimension mm |

| LCFG-01. | 5000 | 1.8 | 1000×1000×1200 |

| LCFG-02 | 10000 | 3.6 | 1800×1000×1200 |

| LCFG-03 | 20000 | 5.4 | 2100×1000×1200 |

| LCFG-04 | 30000 | 7.2 | 2500×1000×1200 |

| LCFG-05 | 40000 | 9 | 3000×1000×1200 |

| LCFG-06 | 50000 | 10.8 | 3500×1000×1200 |

| LCFG-07 | 60000 | 14.4 | 3500×1500×1600 |

| LCFG-08 | 70000 | 16.2 | 4000×1500×1600 |

| LCFG-09 | 80000 | 17.7 | 4500×1500×1600 |

| LCFG-10 | 90000 | 19.5 | 5200×1500×1600 |

| LCFG-11 | 100000 | 21.3 | 5800×1500×1600 |